Benefits of repairing ceramic brake discs using the Rebrake process

Even extremely durable and tenacious carbon ceramic brakes will wear out at some point. Even if manufacturers state a lifetime of up to 300,000 kilometres, the brakes can give up much earlier. What to do? Original replacement brakes from Porsche, Audi, Ferrari etc can easily add up to more than 5,000 EUR. “We don’t just offer our customers the reliable repair of their ceramic brakes, no matter what diameter or how old – we can actually restore their original quality,” states Wolfgang Dietz of FOXX – Automotive Components from Weßling near Munich.

The FOXX Automotive company has established a reliable, high-performance process in “Rebrake”, whereby ceramic brakes undergo carbon ceramic restoration to restore their original quality. This is achieved through each ceramic brake disc being put through a set reprocessing procedure. This consists of several different steps.

Reprocessing procedure for ceramic brake discs in seven steps

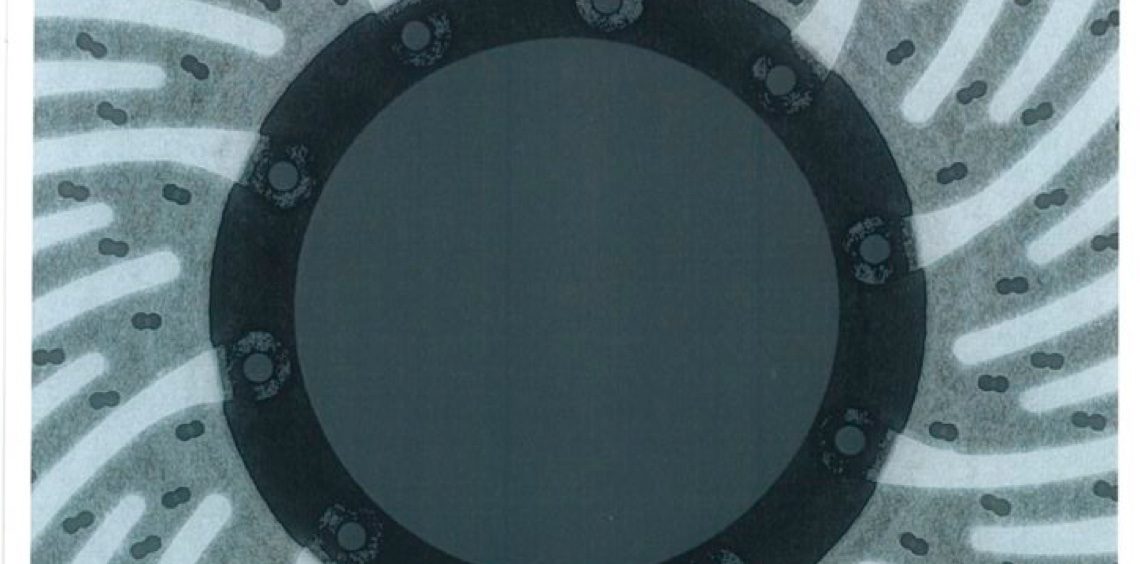

Firstly, the ceramic brake disc is separated from the brake cover, then weighed and X-rayed to rule out any hairline cracks. The disc is then thermally steamed to remove any surface residue and impurities.

In the third step, the ceramic brake disc is face milled, removing all striations. One of three fundamental steps now takes place, which are what make the FOXX Automotive Components process so unique: the roughened discs are treated with carbon polymers in a vacuum. Pyrolysis then takes place at 1,100 degrees Celsius.

Steps four and five are repeated three times so that the resurfaced ceramic brake disc reaches its target weight. Next, the disc undergoes siliconisation at 1,500 degrees Celsius. Final sanding takes place in the seventh and eighth work steps.

Enormous braking performance for high HP cars with restored ceramic brake discs

Treatment with carbon polymers, pyrolysis and siliconisation are what make the FOXX Automotive Components process so unique, and ensure that the carbon ceramic composite that makes up real ceramic brake discs is restored. This composite is especially resistant to heat and abrasion, explaining the enormous braking performance. High HP sports cars with performance levels similar to race cars need to speed up extremely fast but also slow down safely. To achieve this, ceramic brakes are the material of choice.